Table Saws: The Heart of a Woodworker’s Shopfor Woodworking

As someone who’s spent decades in the workshop, I can tell you that no tool is as indispensable as the table saw. It’s the cornerstone of precision woodworking, from ripping boards to creating intricate joinery. Over the years, I’ve used nearly every type of table saw on the market—contractor saws, cabinet saws, and hybrid saws. Each has its strengths, and knowing which one suits your needs can make all the difference in your woodworking projects.

And if you’re just starting out or on a budget, you might be interested in finding the best budget table saw with the most features. In fact, I recently came across a video review where a fellow woodworker went on a mission to find exactly that. You can check out the video here:

1.- Understanding Table Saws: Types and Features

When I first started woodworking, I quickly learned that not all table saws are created equal. The type of table saw you choose depends on your workspace, the materials you work with, and the kind of projects you typically undertake. Let’s break down the main types of table saws and the key features you should look out for.

1.1. Types of Table Saws

- Portable Table Saws (Jobsite Saws): Ideal for carpenters who move between job sites, these saws are compact and lightweight but still offer considerable power. However, they can be less stable than stationary models.

- Contractor Table Saws: A step up in power and stability, these saws are great for more extensive home projects or a semi-permanent workshop setup. They offer a larger table surface and more powerful motors but are still portable enough to move when necessary.

- Cabinet Table Saws: The powerhouse of the woodworking world, cabinet saws are designed for precision and durability. These are best suited for serious woodworkers who have a dedicated workshop space. They’re heavy, stable, and can cut through thick hardwoods with ease.

- Hybrid Table Saws: These combine the best features of contractor and cabinet saws, offering power and precision in a slightly more portable package. A great option if you need a stationary saw but don’t have space or budget for a full cabinet saw.

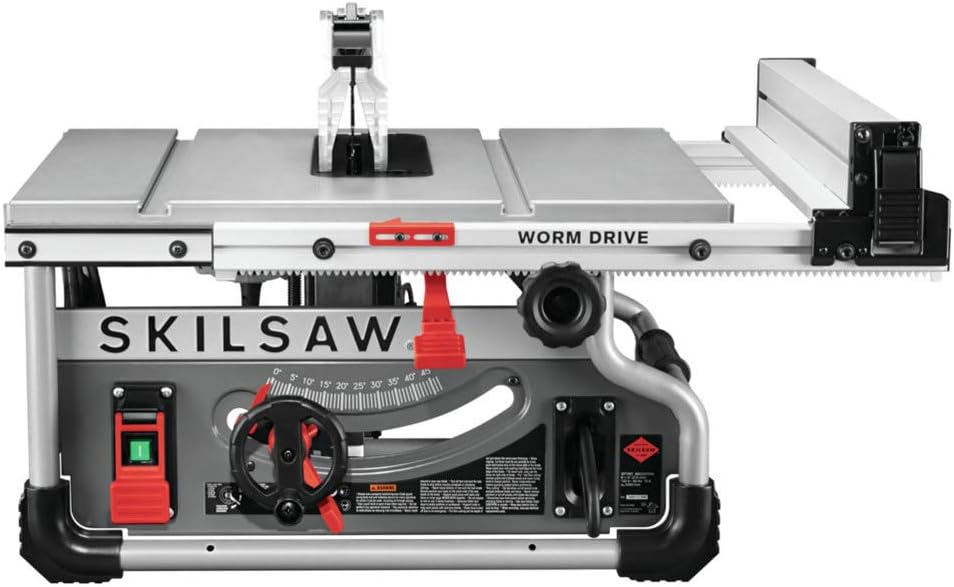

SKIL SPT99T-01 8-1/4″ Portable Worm Drive Table Saw

by Woodwork Labs / Table Saws

SKIL SPT99T-01 8-1/4″ Portable Worm Drive Table Saw. Why is it the best-selling table saw on A…

Read More1.2. Key Features to Consider

- Motor Power: More horsepower (HP) generally means smoother cuts, especially through thicker or harder woods. For most hobbyists, a 1.5 to 2 HP motor is sufficient, but professional woodworkers might prefer a 3 HP or higher.

- Rip Capacity: This is the maximum width of cut the saw can handle. A 24 to 30-inch rip capacity is typically enough for most projects, but if you’re working on larger pieces, look for something with a 36 to 50-inch capacity.

- Fence System: A good fence should be easy to adjust and lock down tightly to ensure precise cuts. The Biesemeyer-style fence is highly regarded among professionals for its accuracy.

- Miter Gauge and Slots: Ensure the miter gauge is solid and the slots are milled accurately. For advanced joinery, an accurate miter gauge is crucial.

- Safety Features: Look for saws with riving knives, anti-kickback pawls, and blade guards. SawStop technology, which stops the blade instantly when it contacts skin, is an excellent safety feature if budget allows.

- Dust Collection: A good dust collection system is crucial for keeping your workspace clean and for your health. Look for saws with at least a 2.5-inch dust port.

2.- How to Choose the Right Table Saw for Your Woodworking Needs

Choosing the right table saw isn’t just about picking the most expensive or the most feature-packed model. It’s about finding a tool that matches your needs, your space, and your budget. Here’s how you can narrow down your choices:

2.1. Assess Your Workload and Space

- For Beginners: If you’re just getting into woodworking, a portable or contractor saw is a great start. They’re versatile, affordable, and don’t require a dedicated space.

- For Intermediate Woodworkers: As your projects grow in complexity, you might find yourself needing more power and precision. A hybrid table saw can offer the stability of a cabinet saw without taking up as much room or draining your wallet.

- For Professional Woodworkers: If woodworking is your livelihood, investing in a high-quality cabinet saw is a no-brainer. The power, precision, and durability these machines offer are unmatched.

2.2. Budget Considerations

Table saws can range from a few hundred dollars to several thousand. Here’s what you can expect at different price points:

- Under $500: Entry-level portable saws. Good for DIY projects and light woodworking.

- $500-$1,500: Mid-range contractor or hybrid saws. A solid choice for most home workshops.

- $1,500 and above: High-end cabinet saws with advanced features and robust build quality, suitable for professional use.

If you’re budget-conscious, like many woodworkers starting out, you’ll find the review video I mentioned earlier helpful. The reviewer highlights a specific budget table saw he purchased from Amazon, which he considers to have the most features for the price. He puts the saw through various tests, including cutting walnut, pine, and plywood, to ensure it maintains accuracy and power throughout.

3.- Detailed Comparison of Popular Table Saws

To help you make an informed decision, here’s a detailed comparison of some of the top table saws available. Each model has been tested and evaluated based on key factors like power, rip capacity, and overall value.

| Model | Type | Motor Power | Rip Capacity | Price | Key Features |

|---|---|---|---|---|---|

| DeWALT DWE7491RS | Portable | 15 Amp | 32.5 inches | $599 | Rolling stand, rack & pinion fence system |

| Bosch 4100XC-10 | Portable | 15 Amp | 30 inches | $549 | Gravity-rise stand, soft-start circuitry |

| SawStop PCS31230 | Cabinet | 3 HP | 52 inches | $3,199 | SawStop safety system, T-glide fence |

| RIDGID R4512 | Hybrid | 13 Amp | 30 inches | $799 | Cast iron table, integrated mobile base |

| Grizzly G0690 | Cabinet | 3 HP | 50 inches | $2,195 | Riving knife, quick-release blade guard |

When I put my budget saw through its paces, I tested it with various materials, including 2×6 lumber, plywood, and even walnut. I was particularly impressed with how well it handled thick cuts and dado grooves, especially given its price. The fence stayed true throughout, which is crucial for ensuring accurate cuts.

4.- Tips for Maintaining Your Table Saw

A well-maintained table saw can last a lifetime. Over the years, I’ve learned that regular maintenance not only extends the life of your saw but also ensures every cut is as precise as possible. Here’s what you need to do:

4.1. Blade Maintenance

- Cleaning the Blade: Resin and pitch buildup on the blade can reduce its cutting efficiency. Clean your blade regularly with a solvent.

- Sharpening: A dull blade is dangerous and produces poor cuts. Replace or sharpen your blades as needed.

- Alignment: Ensure the blade is parallel to the miter slot. This reduces the risk of kickback and ensures accurate cuts.

4.2. Lubrication

- Trunnion Assembly: Periodically, lubricate the trunnion assembly to ensure smooth blade adjustments.

- Fence and Rails: Keep the fence and rails clean and lubricated for easy movement and precise adjustments.

4.3. Dust Collection

- Regular Cleaning: Sawdust buildup can clog the motor and reduce efficiency. Use a shop vac or dust collection system regularly.

- Check the Dust Port: Ensure the dust port is not clogged and is functioning properly.

One thing that surprised me with my recent purchase was the dust collection system—it worked better than expected, especially when I connected it to my shop vac. It kept the workspace clean, which is crucial when you’re working in a small, enclosed area like my garage.

5.- Safety Tips Every Woodworker Should Know

Safety in the workshop cannot be overstated. Here are some crucial safety tips that I’ve followed religiously over the years:

5.1. Personal Protective Equipment (PPE)

- Eye Protection: Always wear safety glasses or a face shield.

- Hearing Protection: Table saws are loud. Over time, exposure can damage your hearing, so use ear protection.

- Proper Attire: Avoid loose clothing and jewelry. They can get caught in the saw.

5.2. Safety Devices

- Riving Knife: Reduces the risk of kickback by preventing the wood from pinching the blade.

- Push Sticks and Blocks: Never use your hands to push small pieces of wood through the blade. Use push sticks or blocks.

- Blade Guard: Keeps your hands away from the blade. Always use it unless the operation requires its removal.

5.3. Operational Safety

- Check the Setup: Before turning on the saw, double-check that the fence is locked and the blade height is correct.

- Stand Properly: Always stand to the side of the blade, not directly behind it. This reduces the risk of injury if a kickback occurs.

- Don’t Rush: Take your time with each cut. Rushing increases the chances of making a mistake or having an accident.

In my case, I make sure to follow these safety protocols every time I use my table saw. While the saw I recently purchased is incredibly feature-packed, it’s also very loud—so I always use hearing protection. The stability of the integrated stand also made me feel much safer, even when making more challenging cuts.

FAQs About Table Saws

Here’s a section to address some of the most common questions about table saws:

What is the difference between a table saw and a miter saw?

A table saw is designed for ripping and crosscutting large pieces of wood, while a miter saw is used primarily for making precise crosscuts and miter cuts on smaller pieces of wood. They serve different purposes but can complement each other in a workshop.

How do I prevent kickback on a table saw?

Kickback can be prevented by using a riving knife, keeping the blade sharp, aligning the fence correctly, and maintaining a firm grip on the wood. Always stand to the side of the blade to avoid injury if kickback occurs.

How often should I replace the saw blade?

The frequency of blade replacement depends on how often you use your table saw and the materials you cut. If you notice burning, excessive chipping, or difficulty cutting, it’s time to replace or sharpen the blade.

What size rip capacity do I need?

For general woodworking, a rip capacity of 24 to 30 inches is sufficient. If you’re working with larger sheets of plywood or need more versatility, consider a saw with a 36 to 50-inch rip capacity.

Can I use a table saw to cut metal?

Table saws are primarily designed for cutting wood. However, with the right blade, they can cut non-ferrous metals like aluminum. Always consult the saw’s manual and take additional safety precautions when cutting metal.

How do I know if my table saw is aligned properly?

Check the alignment by measuring the distance from the blade to the miter slot at both the front and back of the blade. If these measurements are equal, your blade is parallel to the slot. The fence should also be parallel to the blade.

The Table Saw, Your Workshop’s Best Friend

After years of woodworking, I’ve learned that investing in a good table saw is one of the best decisions you can make for your craft. Whether you’re a hobbyist or a professional, the right saw can turn daunting projects into enjoyable tasks. Choose wisely, maintain your equipment, and always prioritize safety. Happy woodworking!

For those on a budget or just starting out, the saw I recently picked up has proven to be a solid performer. It’s not perfect, but for the price, it offers a lot of features that make it a great addition to my workshop.